Five Advantages Of Products

- support customer mould design

- own mould and injection factory

- high quality

- better aftersales services

- competitive price

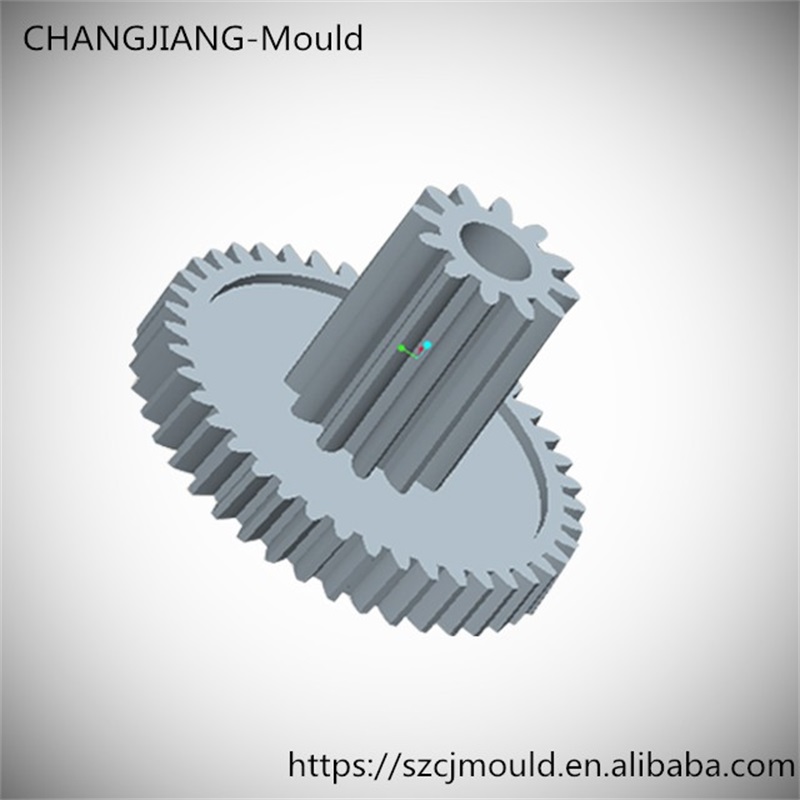

Product Details

Product description:

Mould base:2 plate,3 plate, Hot runner mold base,

Mold core material:DIN2312,2738,2344,718,S136,8407,NAK80,SKD61,H13,PA;

Cavity:Single / Multi cavity to 16 cavties,or custoomer request;

Runner:Cold runner(DME,YUDO,HASCO,or custom),cold runner(pin gate,side,sub-gate,long runner)

Gear size:dia. 3mm to 100mm

Surface request:High Polish, Hight Gloss,or Texturing(MT(mold tech),YS,HN series,EDM )

Design software:NX_UG, Pro/E, Catia, Moldflow, AutoCAD(accept STP file for transition)

Plastic gear material:POM, PA6,PA66,PA46,PEEK, PBT, Teflon

Package:PE bags add export carton for spare parts;

Value added service:Polish,texture,painting,screen printing,turnkey project,EDM eletronic,local service.etc.

Design & Program Softwares:CAD, CAM, CAE, Pro-E, Solid works…etc.

Equipments:High speed CNC, standard CNC, EDM, Wire Cutting, Grinder, Plastic Injection Molding Machine for testing mold from 50-3000T available

Certifications:

Our factory has a strict requirements to our mould and products,and our factory has passed ISO9001:2008 standard,so you can assure the quality about our mould and products.What's more, we provide wonderful after-sell services, any questions just contact us.

Advantages:

1.Mold design is subject to customer's requirement.

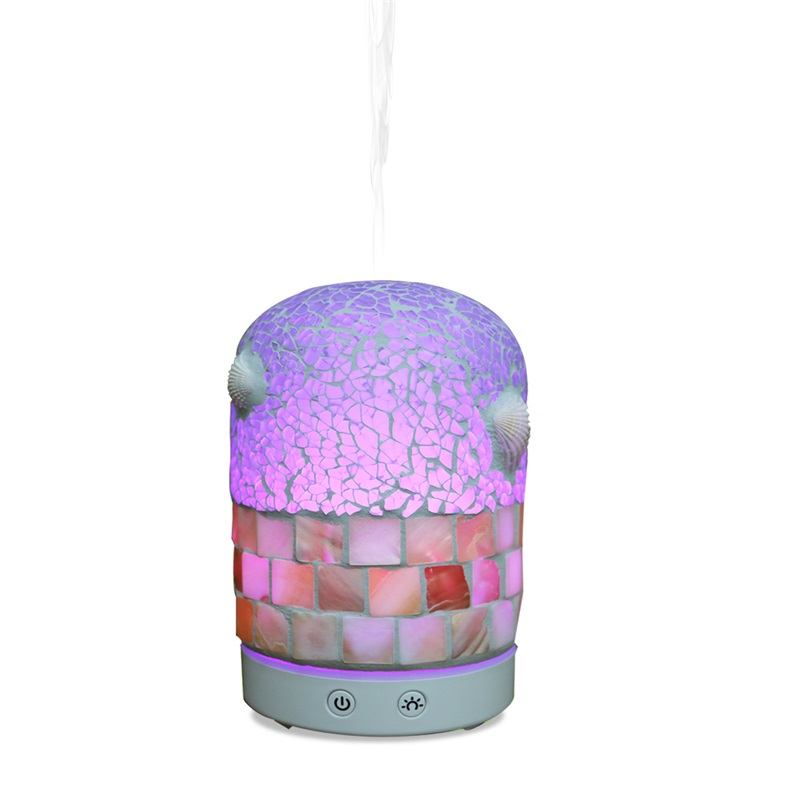

2.Injection molding machine specification of certain plastic,etc.Our products include a variety of vacuum cleaners,and plastic components.These products are widely available to worldclass large companies.We have won a high reputation among clients.Our company provides processing or researching and manufacturing services.We are very interested in the development of new products to meet market demands.

3. Specifications about flow, material, radian and so on, we can fit in all you want.

Our Company:

Chang jiang factory majors in manufacturing of plastic injection mold ,plastic parts, and mouse trap etc. Our main customers are: HOT, Sparoom, Rimport in US, GreenDelta in EU, and Tescom in Japan. We have years of experience in manufacturing, R&D (with own R&D team), quality control and good customer service to our customers. The biggest strength is that, we have our own tooling and mold dept., for which we can wholly control the cost and lead time of product molds, then make more new shapes and cost-effective products to our customers. Under this situation, the new product cycle and cost are relatively superior to other suppliers in the market.

Packing & Delivery:

Packing:Standard export packaging or according to customer requirements

Time:25~30days by sea,4~7 by air

Payment: T/T,L/C,40% deposit,30% upon T1 sample,30% balance before shipment

Inquiry

Shenzhen Changjiang Plastic&Mould Co.,Ltd

Contact Person: Rachel Hong

Department: Sale department

Post: Salesman

Telephone: +86 18682390593

Landline: +86 0755 89690239

Company Address: B9 building, Bao'e industrial area, E'gongling community, Pinghu town, Longgang district, Shenzhen, Guangdong, China

Website: szcjmould.us764.com