Five Advantages Of Products

- kinds of fans of standing and ceiling

- Professional mould manufacturer

- Wonderful aftersale services

- Competitive price

- support customer design

Product Details

Product Description:

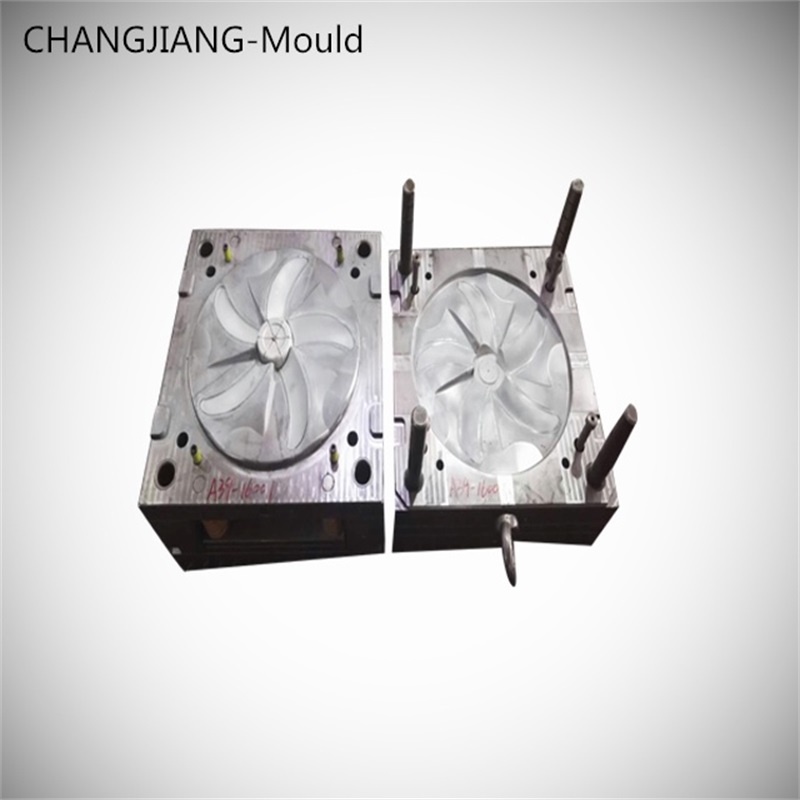

Model Number:A39-17004

Mould material:NAK20,P20,738H,718H, etc

Cavity:Single /Multi Cavity

Runner:Hot Runner Cold Runner

Mould life:100k~500k shots

Surface treatment:SPI standard,Texture

Mould name: Household applince fan parts mould

Mold standard:DME or HASCO

Mold Base:LKM,DME, HASCO, FUTABA

Steel Treatment:Heat Treatment, Nitriding, Chrome Plating

Surface finish:SPI standard, VDI EDM, Texture, etc

Plastic Material:PP, PC, ABS, PE, HDPE, PET, POM, PMMA,etc

Main Market:Europe, USA, Japan, India etc

Our field:Household, Electrical,Medical,Auto-parts,IT parts, etc

Our Service:

1. 20 years of rich experience in mold industry and a wide range of products

2. Main markets covers USA, Europe, Asia

3. Outstanding merchandise and considerate 24 hours on-line customer service

4. Punctual delivery, good quality and satisfy customers request

5. Best after-sale service

6. A number large production lines, strong technical strength and advantage production equipment

Our Company:

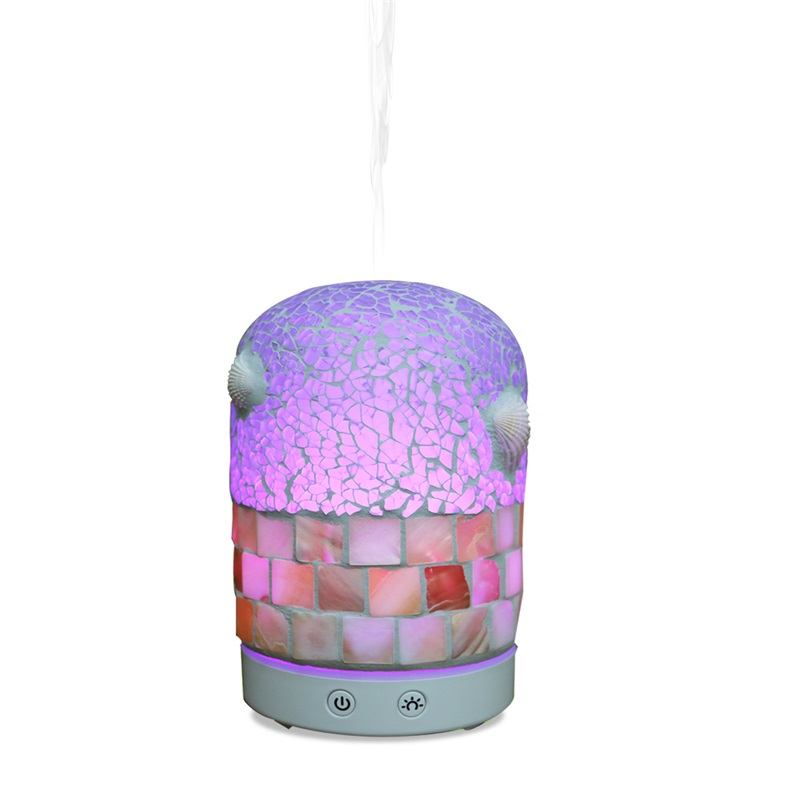

Chang jiang factory majors in manufacturing of plastic injection mold ,plastic parts, and mouse trap etc. Our main customers are: HOT, Sparoom, Rimport in US, GreenDelta in EU, and Tescom in Japan. We have years of experience in manufacturing, R&D (with own R&D team), quality control and good customer service to our customers. The biggest strength is that, we have our own tooling and mold dept., for which we can wholly control the cost and lead time of product molds, then make more new shapes and cost-effective products to our customers. Under this situation, the new product cycle and cost are relatively superior to other suppliers in the market.

Packing & Delivery:

Packing:Standard export packaging or according to customer requirements

Time:25~30days by sea,4~7 by air

Payment: T/T,L/C,40% deposit,30% upon T1 sample,30% balance before shipment

FAQ:

1: Does your company make mould by yourself?

Yes, we are manufacturer with about fifteen years of molding experience.

2: How many kinds of moulds can you make? Only make the moulds?

We can make many kinds of moulds, such as plastic injection moulds, blowing moulds, stamping moulds, die casting moulds and silicone rubber moulds. Besides, we also can produce the final parts for you.

3: What’s the software you will use to check the drawing? And what’s format of drawing you can check?

Our designers and engineers all use AUTO CAD and Soliworks software to check 2D and 3D drawings.We can check the drawings with PDF, AI, DWG (CAD) and STP (3D) or IGS (3D) formats.

4: Will you send me the free sample?

Yes, but you should charge the freight by yourself. We can return the fee if you place a bulk order.

5: How to pack the moulds and products?

For moulds, we will be coated one-layer anti-rust oil first, and then also will be covered thin films on the mould, finally pack into non-fumigation wooden case.And as to products, we will pack into standard export cartons or as per customer’s request to pack.

Inquiry

Shenzhen Changjiang Plastic&Mould Co.,Ltd

Contact Person: Rachel Hong

Department: Sale department

Post: Salesman

Telephone: +86 18682390593

Landline: +86 0755 89690239

Company Address: B9 building, Bao'e industrial area, E'gongling community, Pinghu town, Longgang district, Shenzhen, Guangdong, China

Website: szcjmould.us764.com